General Descriptions

Tanks

Our standard profile is 5′ high 8′ wide. 251 gallons per foot. Our low profile is 4′ high 8′ wide. 195 gallons per foot. Upon request there are other size tanks that can be made.

Tank Materials

The tank is constructed of 3/16″ A 36 steel plate.

The baffles are 3/16 gauge steel with 22″ crawl holes, (off center.)

Tank has a 1/4″ “Z” sub-frame with cross members and end bolsters.

Tank also has 6″ saddle that the tank sits on, rubber padded perma-slats that goes between the truck and the tank frame, bumped dished heads.

Entire tank is welded inside and out.

Tank Mounts

Tank supports are constructed from 1/2 X 3 angle and are welded to the tank sub frame and bolted to the truck frame. We use 5/8 X 7 grade 8 bolts and a 4″ 350lb coiled spring which allows 2″ frame movement on all corners. There are 3 on each side, for a total of 6. We put 4 side shift supports-one on each corner. We use vulcanized permaslat runners that are welded to the tank sub-frame. Tanks can be ordered to meet forest service specs of 52 inches.

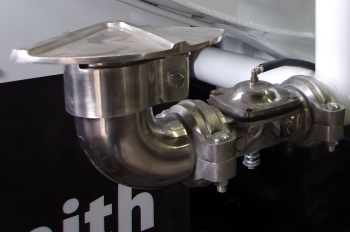

Plumbing

All plumbing is constructed from standard pipe, with weld-on fittings and grooved flex fittings (no pipe threads!). Designed for flexibility and quick removal. All plumbing has drained plugs at low points.

Water Loading Valves

Water loading valves are 1/4″ turn butterfly. They are all labeled for easy operation. We put 8″ X 4″ tank to pump sump line, included is a steel screen inside tank inlet.

Water Pump

Aluminum 4X3 centrifugal. Rated at 1000 gpm. up to 130 psi. grooved ends. Mechanical seal. Stainless steel shaft. Oil lubricated bearings. (Other pumps are available at additional cost.) Pump is powered by Air Shift PTO, and a Spicer Drive line.

Spray Control Valves

Front Spray bar has 2 -3″ adjustable air spray valves. Groove mounted for any position. It comes complete with Splash Heads and Street Flusher Nozzle attachments. Rear spray bar has 2 – 3″ adjustable air spray valves.

Paint

Steel surface is sanded. Metal conditioner is applied. Two coats of primer, and two coats of acrylic enamel paint.

Epoxy Primer Coating

Two step epoxy primer coating is applied inside the tank to prevent rust.

Console Control

Steel console will be mounted between the seats, with stainless steel facing. All control switches are labeled.

Rear Inlet for Hydrant Filling

Hydrant filler will be a 2 1/2″ above tank anti-siphon filler pipe showing at least 6″ of air before entering top of tank. Complete with Cam-lock fittings and 18′ of 2 1/2″ fire hose.

Warranty

Our construction models are warranted for a period of THREE (3) years on the tank and ONE (1) year on the plumbing.

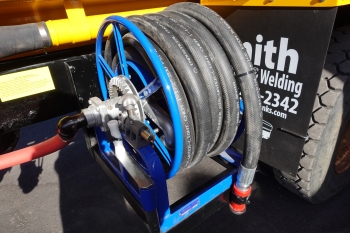

Hose Reel

American Reeling Devices manually operated 1 1/2″ hose reel with 50ft of hose and nozzle.